Product Category

Main Products

No products found

Contact Us

Eric Yuan

Victoria W.

Naomi D.

Product Details

Product Information

| Product Name | Stainless Steel Welded Pipe |

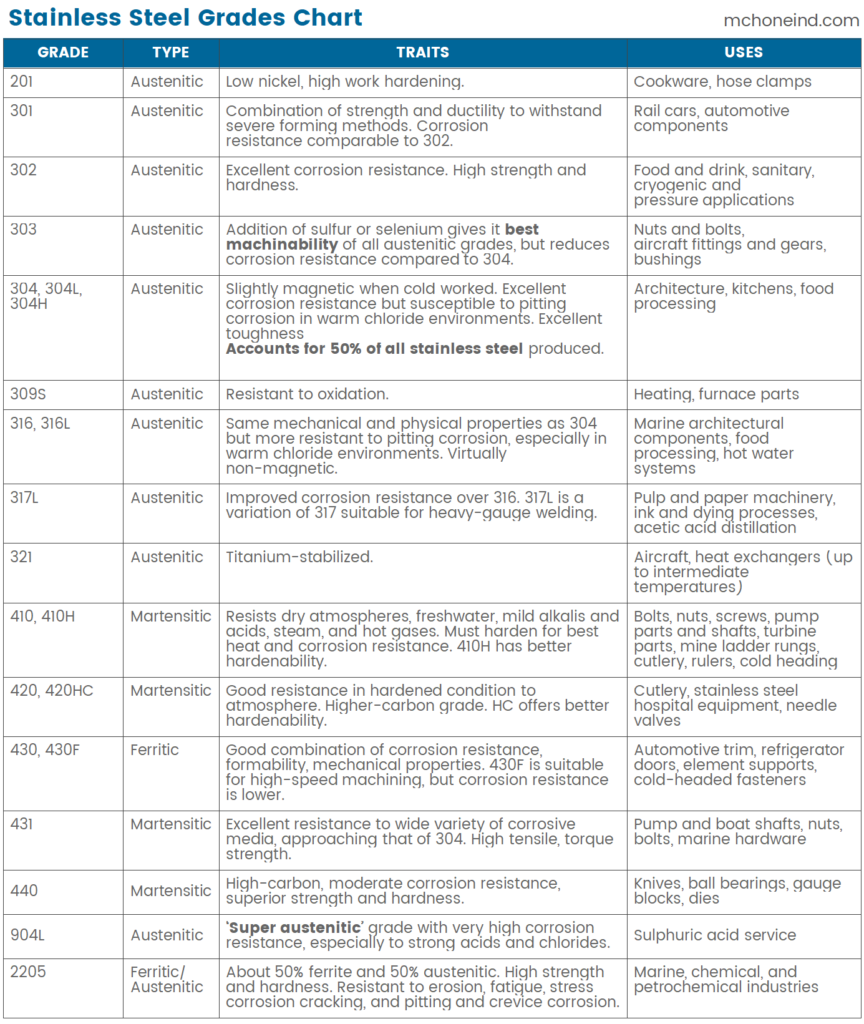

| Material | 200 series: 201, 202 |

| 300 series: 304, 304L, 321, 316, 316L, 316Ti, 347H, 309S, 310S | |

| 400 series: 410, 420, 430, 440 | |

| 900 series: 904, 904L | |

| Duplex: 2205, 2507 | |

| Special: 2507, 316Ti, 316LN, 347H, 317L, 310S, 253MA, RA330, 725LN, 724L etc. | |

| Standard | AISI, ASTM, BS, DIN, EN, GB, ISO, JIS etc. |

| Size | 10*1-2, 12*1-3…20*2-5, 22*2-6…30*2.5-8, 32*2.5-8…40*3-12, 42*3-12…All the way to 508*8-85, 530*8-85…610*8-90, 630*8-90…820*10-95mm |

| Length | Fixed: 6m or as Required |

| Tolerance | According to Standard |

| Surface | NO.1, 2D, 2B, NO.4, HL, BA, 8K etc. |

| Welding | GTAW, PAW, GMAW, FCAW, SMAW, SAW, SW (ARC,CD), RSW, RSEW, PW, ESW, FW, HFIW, LBW, EBW |

| Applications | Power Plant Condenser, Petrochemical, Seawater Desalination, Shipbuilding, Automobile, Electronic Instrument, Water Supply, Pharmaceutical, Dairy Production, Brewery etc. |

| Quality Management | ISO9001, CE, Third Party Testing / Inspection, Certifications Applied for Buyers’ Countries |

| Samples | Kindly Discuss with Sales Assistant |

| Brand | TISCO, Baosteel, Zhangpu, Qingshan, Shanghai Shang Shang etc. |

| Lead Time | Depends on Specifications, Quantity etc. |

| Package | Standard Seaworthy Package or as Required |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Method | T/T, L/C etc. |

|

STANDARDS |

||||

| DIN | EN | ASTM/AISI | UNS | GB/T |

| 1.4310 | X10CrNi18-8 | 301 | ||

| 1.4318 | X2CrNiN18-7 | 301LN | ||

| 1.4307 | X2CrNi18-9 | 304L | S30403 | |

| 1.4306 | X2CrNi19-11 | 304L | S30403 | 00Cr18Ni9 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 | |

| 1.4301 | X5CrNi18-10 | 304 | S30400 | 06Cr19Ni10(GB/T3280-2007) |

| 1.4948 | X6CrNi18-11 | 304H | S30409 | |

| 1.4303 | X5CrNi18-12 | 305 | ||

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 | 0Cr18Ni11Ti |

| 1.4878 | X12CrNiTi18-9 | 321H | S32109 | |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4401 | X5CrNiMo17-12-2 | 316 | S31600 | 0Cr17Ni12Mo2 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31600 | 0Cr17Ni12Mo2 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN | S31653 | |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti | S31635 | |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 | |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 | |

| X10CrNiTi18-9 | 347 | 0Cr18Ni11Nb | ||

| 1.4512 | X6CrTi12 | 409 | 0Cr11Ti | |

| S41000 | 0Cr13 | |||

| 410 | 1Cr13 | |||

| 420J1 | 2Cr13 | |||

| 1.4016 | X6Cr17 | 430 | 1Cr17 | |

| 1.4118 | X40CrMo15 | 440A | S44002 | 8Cr13 |

| 1.4112 | 440B | S44004 | 9Cr13 | |

| 1.4125 | 440C | S44003 | 11Cr18 | |

| 440F | S44020 | |||

| 1.4539 | X1NiCrMoCu25-20-5 | 904L | N08904 | 00Cr20Ni25Mo4.5Cu |

| 1.4547 | X1CrNiMoCuN20-18-7 | S31254 | ||

|

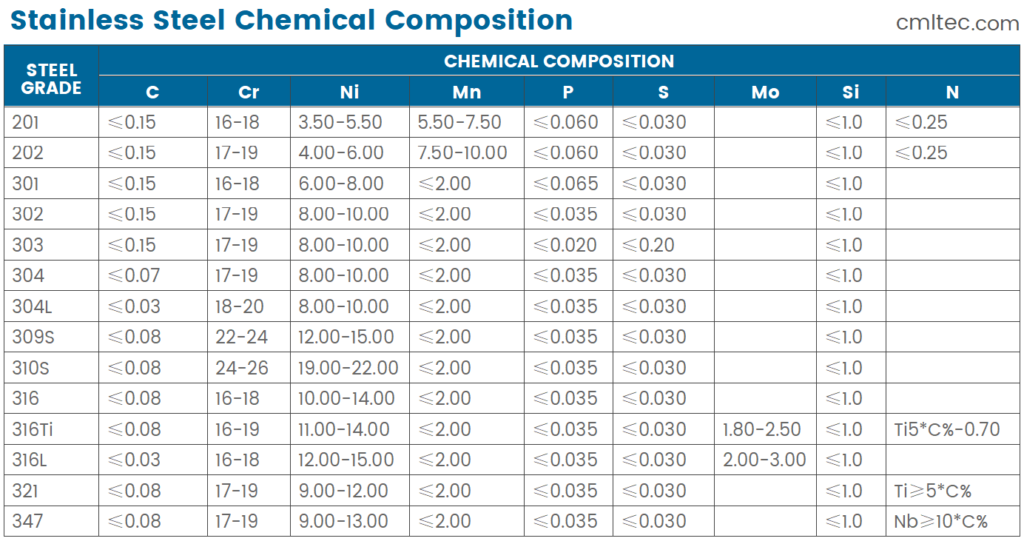

CHEMICAL COMPOSITION (%) |

|||||||||

| Grade | C, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Si, ≤ | Cr | Ni | Mo | N, ≤ |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | – | – |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | – | – |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – |

| 321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | – | 0.1 |

| 201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 16.0-18.0 | 3.5-5.5 | – | 0.25 |

| 301 | 0.15 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 6.0-8.0 | – | 0.1 |

| 302 | 0.15 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 8.0-10.0 | – | 0.1 |

| 303 | 0.15 | 2 | 0.2 | ≥0.15 | 1 | 17.0-19.0 | 8.0-10.0 | – | – |

| 305 | 0.12 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 11.0-13.0 | – | – |

| 308 | 0.08 | 2 | 0.045 | 0.03 | 1 | 19.0-21.0 | 10.0-12.0 | – | – |

| 309S | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | – | – |

| 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0-26.0 | 19.0-22.0 | – | – |

| 310H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 24.0-26.0 | 19.0-22.0 | – | – |

| 316Ti | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 |

| 317L | 0.03 | 2 | 0.045 | 0.03 | 0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | 0.1 |

| 321H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-12.0 | – | – |

| 347H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-13.0 | – | – |

| 348H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-13.0 | – | – |

| 2205 | 0.03 | 2 | 0.03 | 0.02 | 1 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

| 2507 | 0.03 | 1.2 | 0.035 | 0.02 | 0.8 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 |

| 410 | 0.08-0.15 | 1 | 0.04 | 0.03 | 1 | 11.5-13.5 | – | – | – |

| 420 | 0.15, ≥ | 1 | 0.04 | 0.03 | 1 | 12.0-14.0 | – | – | – |

| 430 | 0.12 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | – | – |

| 440A | 0.60-0.75 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | ≤0.75 | – |

| 440B | 0.75-0.95 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | ≤0.75 | – |

| 440C | 0.95-1.20 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | ≤0.75 | – |

| 440F | 0.95-1.20 | 1.25 | 0.06 | 0.15 | 1 | 16.0-18.0 | 0.5 | – | – |

| 800H | 0.05-0.10 | 1.5 | 0.045 | 0.015 | 1 | 19.0-23.0 | 30.0-35.0 | – | – |

| 904L | 0.02 | 2 | 0.045 | 0.035 | 1 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.1 |

| 15-5 PH | 0.07 | 1 | 0.04 | 0.03 | 1 | 14.0-15.5 | 3.5-5.5 | – | – |

| 17-4 PH | 0.07 | 1 | 0.04 | 0.03 | 1 | 15.5-17.5 | 3.0-5.0 | – | – |

| 17-7 PH | 0.09 | 1 | 0.04 | 0.04 | 1 | 16.0-18.0 | 6.5-7.75 | – | – |

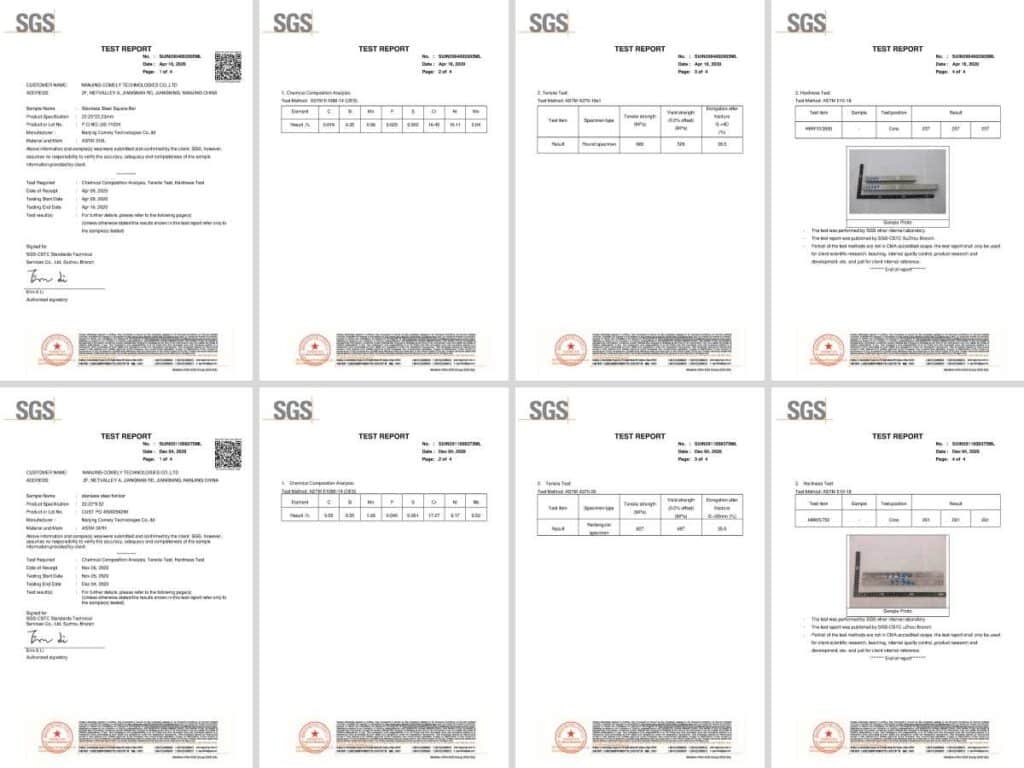

Test Reports

We welcome all the 3rd-party inspections including SGS reports

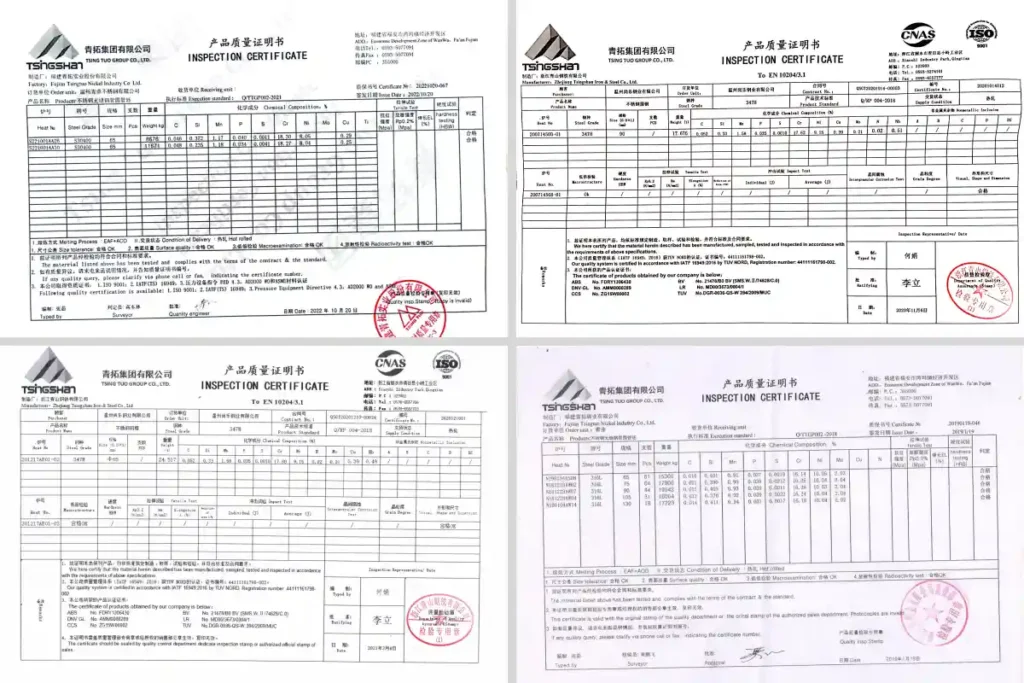

Raw Material Reports

We choose raw materials

only from big mills

for their better quality

Mill certificate for raw materials will be offered before delivery

Exhibitions

Packing