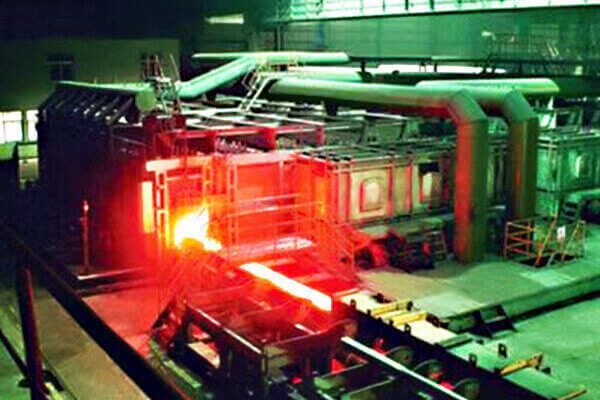

The annealing process of stainless steel is a heat treatment technique that involves heating a material, in this case, stainless steel, to a specific temperature and then cooling it slowly to modify its internal structure and properties. The annealing process for stainless steel involves heating it to a temperature of between 1040°C to 1120°C and holding it at this temperature for a specified period, after which it is slowly cooled down in a controlled manner.

The annealing process has several advantages for stainless steel, including:

- Increased Ductility: The annealing process makes stainless steel more ductile, which means it can be bent or formed into shapes without cracking or breaking.

- Improved Machinability: Annealing makes the stainless steel easier to machine, which can help reduce production time and costs.

- Reduced Hardness: The annealing process reduces the hardness of the stainless steel, which can make it easier to work with and less likely to crack or break.

- Stress Relief: The annealing process can relieve internal stress in the stainless steel, which can improve its overall performance and reduce the risk of failure.

- Improved Corrosion Resistance: Annealing can improve the corrosion resistance of stainless steel by reducing the risk of stress corrosion cracking and other forms of corrosion.

Overall, the annealing process is an important heat treatment technique for stainless steel that can improve its properties and performance in a variety of applications.