Quality Assurance

Our persistence in strict quality control is always the prerequisite in our goals

Our approach to quality

Every business starts with trust, diligence, and commitment. At cmltec, we take these concepts very seriously. We provide clients not only with a durable end product but also with the assurance of superior quality standards. Offering comprehensive quality control over all processing, workmanship, and factory and work environments is our number one priority.

Quality matters to us

We keep improving our efficiency from some details without any impact on the quality. We utilize the full-automatic production and packaging platform to all production lines. We have in-house cranes and forklifts for the safety of our staff and high efficiency. As a result, we save up to 3/4 times than other manufacturers in the industry.

Our Inspection Standard

All products from Cmltec are manufactured strictly according to the international standards. Download the manufacturing/inspection standard lists.

ASTM A554 (EN 10296-2 & EN 10219-2) Standard

ASTM A249 Standard

ASTM A269 Standard

ASTM A270 (EN 10217-7 & EN 10357) Standard

Quality Control Approach

Precise and Reliable.

#1 Raw Material Inspection

Careful inspection of the raw materials to eliminate potentially flawed materials.

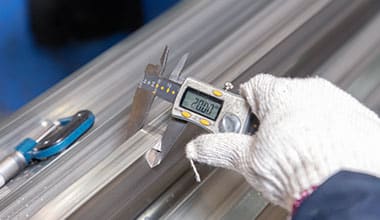

#2 Dimension Inspection

A thorough inspection to ensure the sizes comply to the precise dimensional tolerance range.

#3 Surface Inspection

Strict test of the surface brightness and texture, fine roughness, no blister or black lines.

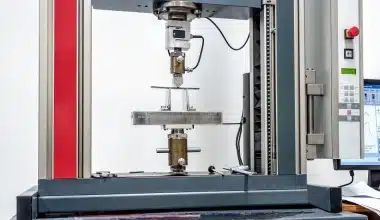

#4 Mechanical Properties Testing

Tensile, hardness, reverse bend tests to ensure proper yield stress and tensile strength.

#5 Eddy Current Testing

Uses electromagnetic induction to identify defects and guarantee the air tightness.

#6 Intergranular Corrosion Testing

Test to make sure the piping is anti-corrosion, suitable for a specific or generic environment.

Third-Party Inspection Report

Double assurance available here!

Well-Selected Raw Materials

At CMLTEC, we adhere to a rigorous selection process for raw materials, exclusively sourcing from reputable and established mills. Although the cost may be higher, we prioritize the acquisition of materials of superior quality. Rest assured that we will provide mill certificates for all raw materials prior to delivery, guaranteeing their authenticity and traceability.

- Download Testing Report

Final Products

At CMLTEC, we understand your need for precise, hard, and bright products. To ensure quality, we maintain a comprehensive record of quality data for every batch of products. We also offer a range of inspection methods to meet your specific requirements.

· Mill Certificate For Raw Materials

· Our Testing Certificate For Final Products

· SGS Test Report Available at Customer’s Cost

- Download Testing Report